Customized multi axis machining parts

Item: Customized machining machined stainless steel industry part.

With the first-class precision machining equipment and operating skills, we have completely confidence to help customer from sample manufacturing to mass production, from rough machining to various surface treatment.

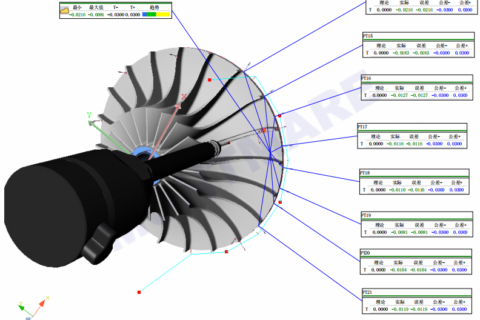

We can supply from engine machining parts to 4 or 5 multi axis machining parts.

Our machining capacity:

| Material: | Stainless steel 201/303/304/400/316,etc; Steel Q235,20#,45#,1020,1045,etc; Aluminum LD5/LD7/66061/6063/7075/5052, etc; Brass C36000(C26800), C37700(HPb59),C38500(HPb58),C2200(CuZn37), C28000(CuZn40) etc. |

| Process: | Raw material cutting, Turning, CNC lathe machining, CNC milling, CNC grinding; CNC boring; Drilling, Surface treatment. |

| Surface treatment: | Hardness anodizing black/clear, Polishing, Electro-polishing, Plating, etc. |

| Tolerance: | +/-0.001mm or +/- 0.00004″ |

| MOQ: | 1 piece. |

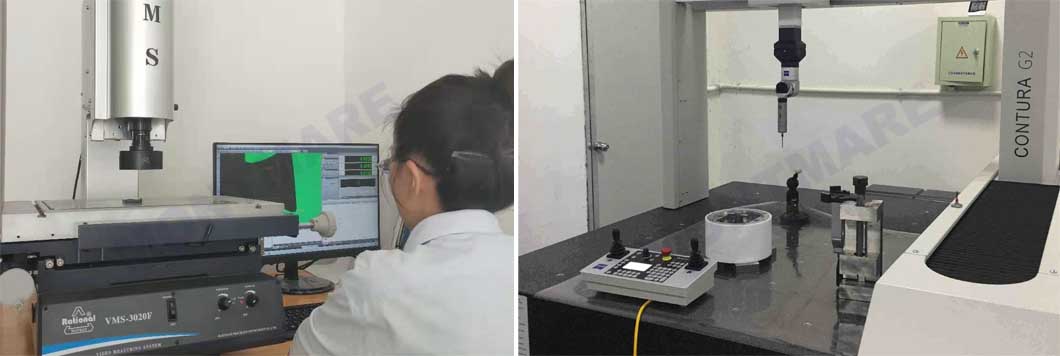

| Testing equipment | CMM, 2D projector, Hardness testing, UT inspection machine, Roughness tester, Hardness tester, Height tester, etc. |

| Packaging: | Seaworthy packing or customers’ requirement |

| Delivery: | 15-30 days after prepayment. |

Multi-axis machining process:

Part of our machines:

Strict inspection:

All the parts will be 100% inspected strictly. CMM report and 2.5D projector report will be issued to you before delivery generated by our precision testing machines.

Excellent packaging:

Our goods will be delivered within enough seaworthy packaging, your required individual packaging is also available.